HEAT EXCHANGERS

- Small sizes

- High efficiency

- Very good price

- Short delivery term

- High life – up to 15 years

- Hig quality

- Operation temperature up to 1250 oC

FLUE GAS - AIR

- Manufactured of heat-resistant or stainless steels.

Operation up to 1150 oC - Practical implementation of the projects with dust content up to 250 g/Nm3

- Working with abrasive and chemically aggressive compounds.

- Dimensions and costs are far less (6-8 times) than using any tubes analogues.

- “Free designing” – equipment replacement without project adjustment; existing connections of the heat exchangers are fully retained.

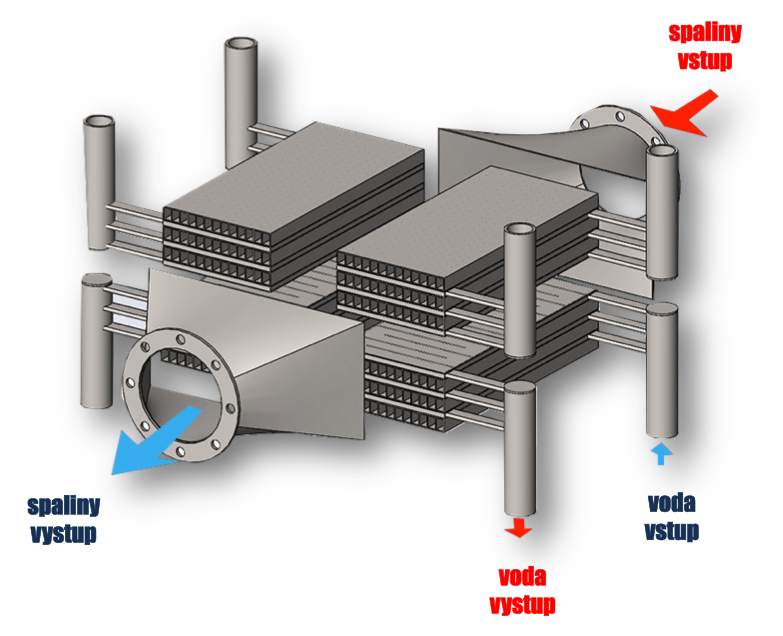

FLUE GAS - LUQUID

- Wear-resistant steels are used. The steels increase wearing capacity 3-5 times against standard corrosion-resistant steels and 5-10 times against low-carbon steel used in gas ducts.

- The heat exchangers channel section is selected in the way that the flue gas velocity exceeds the channel scouring velocity.

- The modular design of the heat exchanger improves its maintainability . Of one of the sections is worn out, it is fully replaced. Or the most and the least worn sections are interchanged. At that it is permissible to leave other heat exchanger section unchanged if they are operational.

Политика конфиденциальности

Редактируемый текст

Данный сайт использует Cookie

Редактируемый текст